Previous industrial projects

We have years of experience in providing services and solutions to industrial partners worldwide. Here, you can find a list of projects we have participated in. For more information about what services we offer, go to Our services page.

In 2023, ELECNOR sought assistance from CDIF-UPC to address high vibration issues in a Kaplan turbine at Speed No Load, which were hindering its operation. Through advanced tests and specialised signal analyses, we identified the root cause of the problem.

By collaborating with ELECNOR and Tractebel ENGIE, a solution to eliminate the vibrations was found. Implementing minor modifications to certain mechanical components could effectively eliminate the strong vibrations. Subsequently, multiple trips to Angola were conducted during various phases of commissioning for the new units. At present, all three units are fully operational and supply electricity to the Lubango area in Angola.

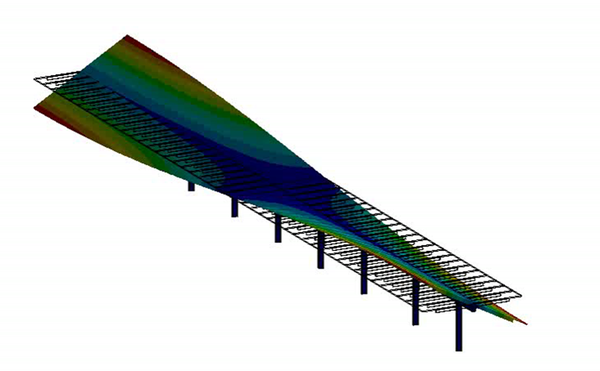

Solar power installation is increasing a lot in the last years in order to enhance renewable energies. Solar trackers are the most common structures to convert solar energy to electricity. These trackers are exposed to large wind dusts that sometimes endanger the structural stability of the structure. Flutter and torsional galloping are some dynamic problems that those slender structures can suffer, leading to large vibration amplitudes and, at the end, to the failure. In this project, those phenomena are studied experimentally and by means of numerical simulation. A monitoring system is installed in a power plant to control the vibration of the solar tracker. CFD and FEM simulations are also carried out in order to study the problem.

- Online monitoring of solar trackers

- CFD numerical simulation of the solar pannel under wind excitation

- FEM Numerical simulation of the solar tracker

Several years of monitoring of hydraulic units by means of online and off-line monitoring systems. These units are located in different places in Spain. Several failures and problems have been detected and solved to ensure a safe operation of the hydraulic units.

This project was possible thanks to the Industrial doctorate program from AGAUR and Generalitat de Catalunya. Within this programme, both industry and university collaborate to improve the knowledge and research in a certain topic.

In this case, the company VAK KIMSA collaborated with CDIF in order to study the dynamic behaviour of industrial agitators. Due to the current demand in the food and pharmaceutical industries, there is a need for a reduction in time of production as well as flexibility in their machines. This leads to changes in the work conditions which can alter the dynamic response of the machine and produce different issues and failures. In this project, the dynamic response of industrial agitators is studied from the experimental and numerical points of view. Failure analysis has been implemented as well as monitoring of the machines.

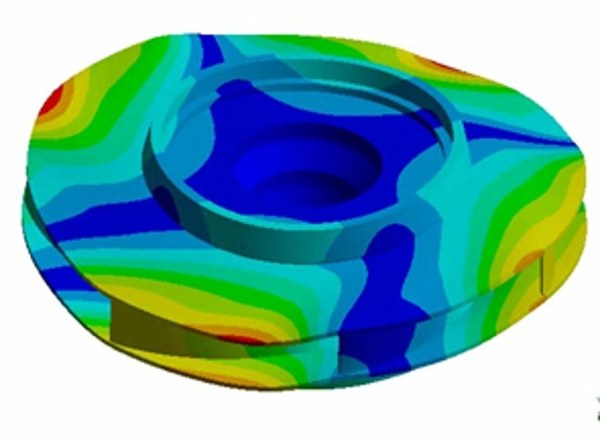

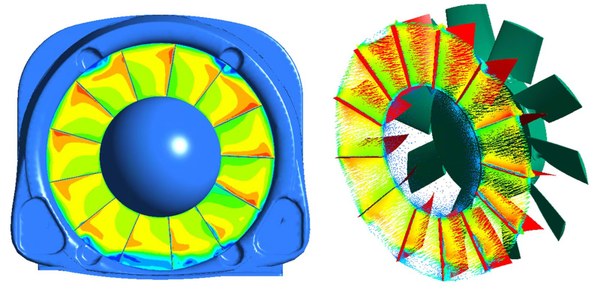

The dynamic behavior of a pump-turbine prototype is studied. Experimental investigation on natural frequencies, damping and mode-shapes of a pump-turbine impeller have been carried out, as well as numerical simulations. However, during the investigation in the prototype several unknowns about the dynamic response of the impeller appeared due to the complexity of the problem studied. To understand how all the possible parameters which interfere in the dynamic response of the impeller affect its natural frequencies, damping and mode-shapes, it was decided to carry out different investigations on simplified models in the laboratory.

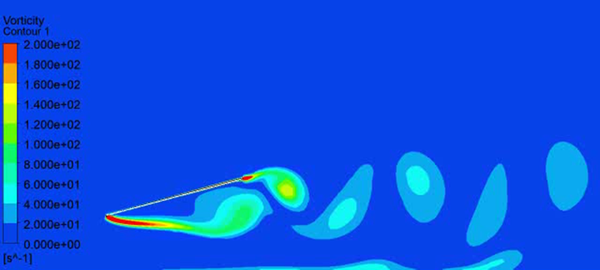

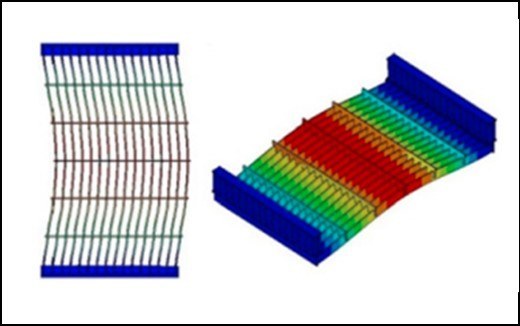

Trash racks are large structures that are fully submerged in water and located in the hydraulic circuits to prevent debris and large bodies from entering the turbine. These structures are prone to suffering fatigue damage. Broken bars are rather common, which can produce damage in the turbine and other hydraulic components. In this project, the dynamic behavior of trask racks was studied experimentally and by means of simulations.

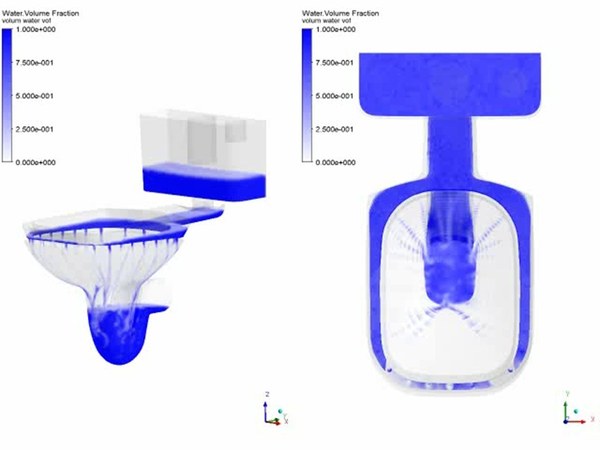

CFD simulations for different chambers:

- Dosing machine

- Sterile chamber

- Depyrogenation tunnel

In a collaboration with Prof. Eduard Egusquiza and CDIF, Mediaclinics launched new hand dryer models that combine technology and design to provide an effective and practical hand hygiene solution to public and commercial areas.

- Production analysis of the mini hydropower plants El Roig and La Corba (GENESIS) 2011

- Analysis of air injection to reduce instabilities in a Francis turbine (IBERDROLA) 2010

- Analysis of the behavior of a large Howell valve located in Susqueda Dam (ENDESA) (2011)

- Fluid dynamic analysis of a large siphon TERSA (2010-11)

- Analysis of the air injection effects in an upgraded Plant with Francis turbines 90MW Mequinenza (2008-10)

- Analysis of the dynamic characteristics of a Francis runner of a pump turbine runner, VA TECH HYDRO AG (Switzerland) 2008-2009

- Measurement and analysis of the Hydro Power Plant of Fratel Kaplan 50MW (Portugal) ALSTOM

- Vibration analysis of the Picote Hydropower Plant Francis 70MW (Portugal) Energias de Portugal EDP

- Design of a Trash-rack for a Hydropower Plant (VOITH Tolosa) (2008)

- Analysis of a large penstock fluid dynamics DRAGADOS (2008)

- Vibration analysis of Soutelo hydropower plants (pump-turbine unit 80MW) IBERDROLA (2007)

- Vibration analysis and diagnostic of the Kalayaan Pump storage plants (4 units of 180MW). Kalayaan, Laguna, Philippines, June July 2005, for IMPSA/CBK

- Vibration analysis and diagnostic of the Macagua Powerplant, Puerto Ordaz (Venezuela) EDELCA June 2006

Share: