Research lines

Our research work is mainly based on and applied to Fluid Dynamics and Turbomachines.

What do we do?

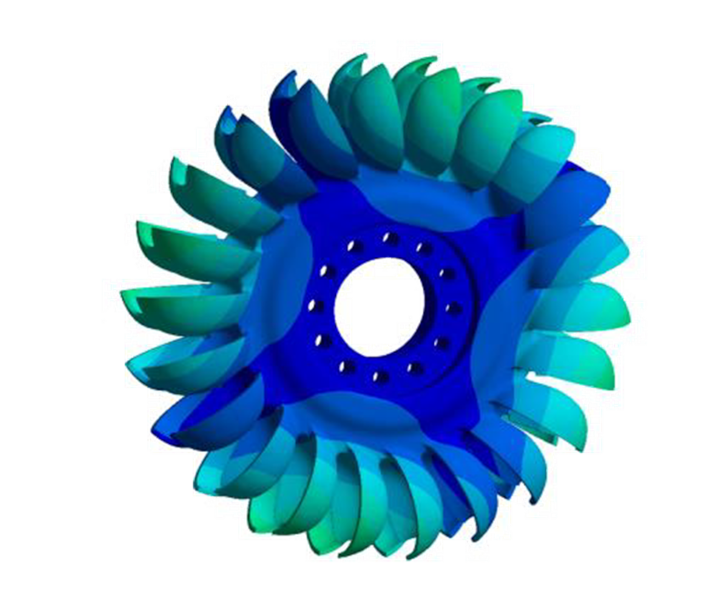

We focus on fluid-structure interaction phenomena on both simple geometries, such as disks or plates, and complex geometries, like the turbomachine runner. The acquired knowledge in simple geometries is applied to the study of large scale turbine power generation groups. This research includes the study of the dynamic excitations generated by the flow and the structure's dynamic response to said excitations.

The dynamic response analysis of the structure is of paramount importance in order to avoid excessive vibration and stresses than can lead to a failure.

A hydraulic turbine runner is a complex structure submerged in water, rotating inside an enclosure with very small gaps to the stationary parts. Under these conditions, the added mass and damping effects influence the modal response of the structure, which generates uncertainties when estimating vibration modes, frequencies and the amplitude of the vibration phenomena. On the other hand, with the trend of increasing power concentration in generation groups and the trend to work at off-design conditions, the exciting forces over the runner are becoming more intense and unpredictable. Rotor-stator interaction, wake interaction and cavitation have a primal role in the excitation phenomena.

How do we do it?

We conduct our research by using the following techniques:

- Transient flow numerical simulation (CFD) and structural response simulation (FEM).

- Experimentation in power plants as well as in basic structures and reduced scale models.

- Data gathering on real generation groups.

- Signal analysis for vibration data.

- AI (Artificial Intelligence) applied on monitored groups.

Our know-how and experience gathered over the years are applied to the simulation and analysis of the vibrational behavior in advanced monitoring, damage diagnosis and predictive maintenance.

Share: