New paper by Navam Shrivastava (IIT Roorke) published in collaboration with CDIF

Nov 25, 2025

The work, part of the SPARC programme, has been published in the Engineering Failure Analysis journal

CDIF and Indian Institute of Technology Roorkee (IIT Roorkee) have collaborated in the publication of "Numerical analysis of stress distribution in a Pelton bucket under varying operating parameters" by Navam Shrivastava. Both institutions have cooperated under the SPARC programme, an initiative of the Government of India's Ministry of Education.

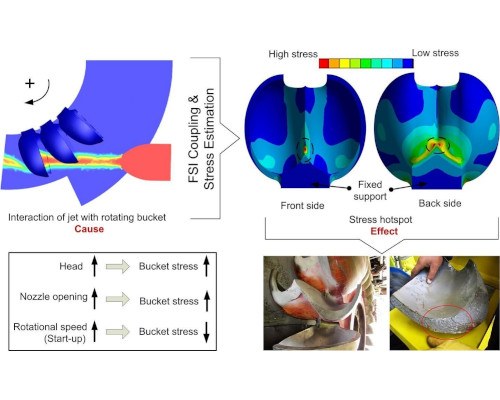

In his work, Shrivastava explores how key operating parameters such as head, nozzle opening, bucket position and rotational speed affect stress distribution in a Pelton bucket by using Fluid-Structure Interaction (FSI) in a transient simulation framework to perform numerical analysis of the stress.

We congratulate Navam Shrivastava for his work and look forward to further collaboration.

Read the paper's abstract here:

Pelton turbine buckets are subjected to high fatigue damage due to the cyclic nature of jet impingement during operation. The stress intensity varies instantaneously and is influenced by operating conditions. In this study, several parameters such as bucket position, plant head, nozzle opening, and sub-synchronous rotational speed representing start-up conditions are considered for analyzing stress. Numerical analysis of the stress was performed using Fluid–Structure Interaction (FSI) in a transient simulation framework. The air–water interface was captured using the Volume of Fluid (VOF) model, and one-way coupling was used to transfer pressure data for structural analysis. The location and intensity of maximum stress were found to vary with bucket position due to pressure fluctuations. In the root region, peak stress occurred when the jet was perpendicular to the splitter, on both front and back surfaces. In the cut-out region, maximum stress on the front surface was observed at jet entry, while on the back surface, it occurred as water leaves the bucket. A 5% increase in head resulted in an approximate 11% increase in maximum stress on both the front and back surfaces of the bucket. Further, the cut-out region showed the greatest structural sensitivity in terms of relative stress variation during the shift from sub-synchronous to nominal runner speeds and dynamic bucket motion. This study emphasizes the need for maintaining stable head conditions to mitigate stress build-up and the optimization of nozzle opening during sub-synchronous to synchronous transition to enhance the structural reliability of Pelton turbines.

Share: